Dell sources gold from motherboards protecting mother earth and you can wear it!

We are victims of our highly technological anthropocene, hopelessly addicted to novelty and speed. We hop from one latest upgrade to the next, never looking back despite the uneasy awareness that the discarded components of our electronic waste are leaching toxins like mercury, lead, cadmium, acids into our precious soil and waterways. In 2018, we humans tossed out our unwanted iPhones, PC’s, and all manner of electronic devices big and small to the tune of over 49 million tons of it world-wide. As reported our article Global E-waste: Scourge and Opportunity. Shockingly, e-waste accounts for 70% of all overall toxic waste in the United States.

E-waste is a serious threat, but fortunately, there is presently some progress toward mitigation. New methodologies are being designed to reduce and eliminate human exploitation and the harsh environmental harm and carbon emissions associated with traditional metal extraction from both the earth and electronic waste.

One significant actor in a new corporate ethos is Dell, Inc., ironically a venerable manufacturer of the very problem of e-waste proliferation. Despite being one of the largest multinational technology companies on the planet, Dell has shown a serious commitment to closed-loop sustainable practices for almost 15 years. In case you are unfamiliar with this brand, it was conceived in 1984 by Michael Dell. It develops, sells, repairs, and supports computers and related products and services world-wide. In 2004, Dell became the first company in the industry to establish a global consumer recycling-program. To facilitate their closed loop modus operandi, they focus on practical designs that take into account energy efficiency, require fewer materials, and build in ease of repair, disassembly and recyclability. Dell prides itself on responsible sourcing, and component materials often come from equipment recuperated from numerous drop-off locations like Goodwill Industries in the US. Dell mines its own waste stream. The closed-loop recycling supply chain involves a series of steps for device disassembly: sorting, shredding, melting and blending.

There is incentive, private as well as corporate, to profit from some of the built-in precious metals that enable the conductivity we so depend upon. A ton of used motherboards has up to 800 times more gold than a ton of gold ore and dumped e-waste is estimated to contain over $60 million in gold and silver yearly, not counting copper, platinum and other precious and rare metals. But is there a safe way to extract it?

The most common secondary extraction practices from recuperated electronic equipment uses a combination of hydrochloric acid and nitric acid which can have deleterious consequences. Other techniques using milder acids have also been developed with less potential to cause adverse effects to the environment. Online Youtube instructions can be found for individuals up for small kitchen-scale harvesting. Every method has its own degree of drawbacks, but Dell has employed a system that is comparably friendly to the environment. According to Trucost, a leader in risk assessment with respect to climate change, natural resource constraints, broad and social, economic factors, Dell has adopted an industrial scale recycling process that is 99% less harmful to the planet than the mining of virgin gold.

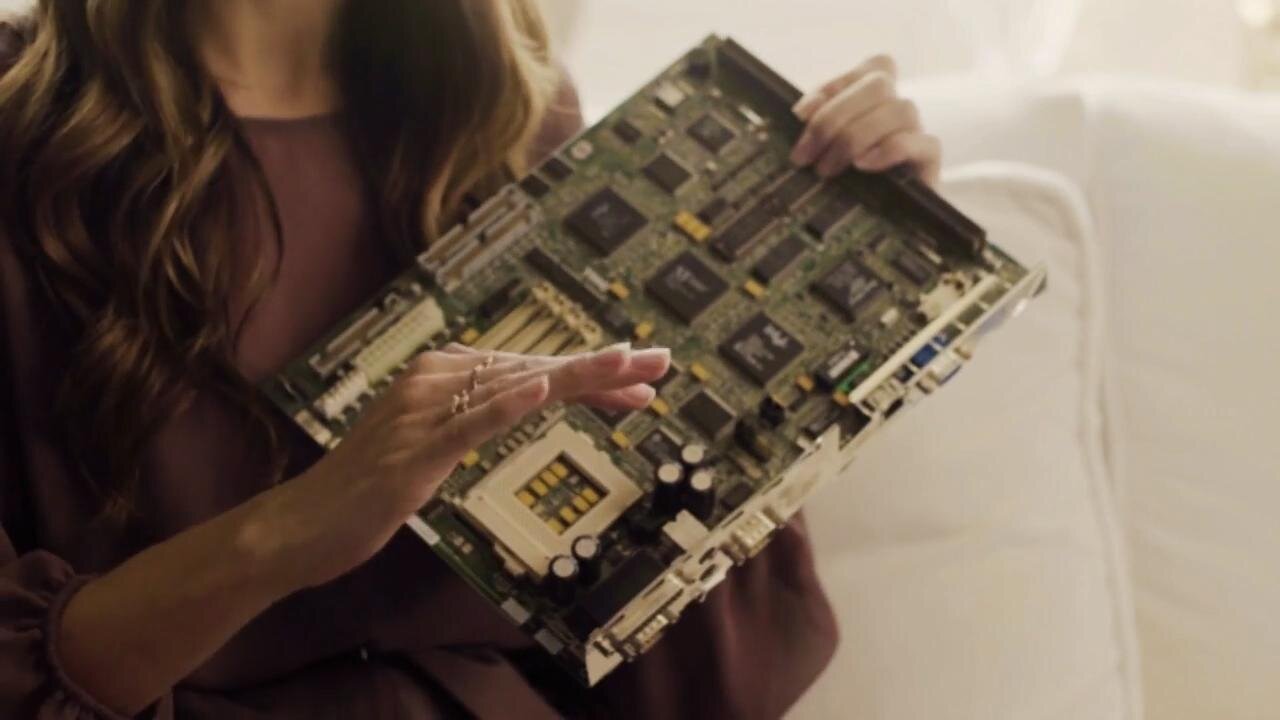

In January of 2018, Dell became the first PC manufacturer to use recycled gold from its own waste stream. Partnering with Wistron GreenTech, a recycling division of Taiwan-headquartered original design manufacturer Wistron Corp., they extract the gold from motherboards electro-chemically and then melt the gold into bars for easy transport to Taiwan who will use it to create a “gold salt bath. ” Components for new motherboards are then dipped in this bath to coat them. On average, Dell uses about seven thousand pounds of gold in its products every year and they expect to be able to manufacture millions of new motherboards with their own recovered gold.

Also in early 2018, Dell moved into the world of fashion with another new partnership, joining forces with Bayou with Love and actress, entrepreneur, and environmentalist Nikki Reed. She calls her line of 18-carat gold rings, earrings and cufflinks sourced from Dell “The Circular Collection.“ According to Dell, it takes six motherboards to make a ring. As Bayou with Love puts it: “Sustainable fashion is now, not later, and conscious consumption is an everyday opportunity to make a better world.”

Who can argue with gold harvested from massive amounts of toxic e-waste that can be had with overall 99% less impact on the planet than mined gold? May sustainability rule!

-Denise Domergue

Banner Image: Artist: Veronika Richterová

Photo by Michal Cihlář